Medical Waste Incinerators for Covid19 Coronavirus Disease For United Nations WHO Items/Model TS100(PLC) TS150(PLC) TS300(PLC) TS500(PLC) Burn Rate (Average) 100 kg/hour 150 kg/hour 300 kg/hour …

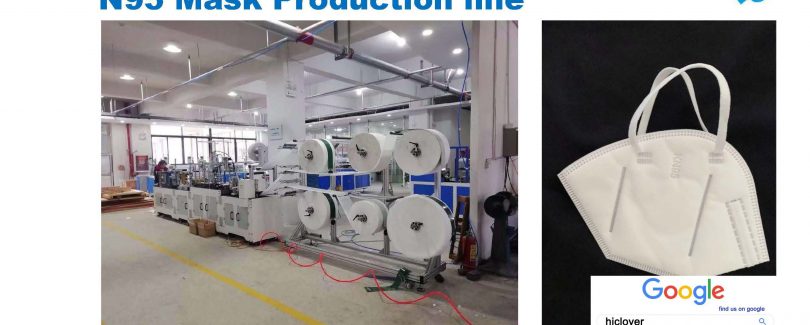

Continue ReadingN95 Face Mask Machine Production Line on Sale Now! $250,000USD per set

N95 Face Mask Machine Production Line on Sale Now! $250,000USD per set N95 Face Mask Machine Production Line on Sale Now! $250,000USD per set l Dimension(L*W*H): …

Continue Readingmedical surgical face mask machine

Zhangjiagang Tengxiang Machinery Co., Ltd. Mobile: 0086-13962221749(whatsapp) Wechat: chncheumg Email: zhangzhonghua@txmc.com.cn 平面口罩机参数: Semi-Automatic Mask Machine l Power supply: 3.3KW mono phase l Mask Size: 175mm*80-100mm (two or three …

Continue ReadingSmall Scale Medical Waste Coronovirus (Covid 19) Incinerator 30 kgs per hour Model TS30 PLC Auto Control

Items/Model TS30(PLC) Picture Burn Rate Average 30 kg/hour Feed Capacity Average 60kg per feeding Control Mode PLC(Programmable Logic Controller Incinerator) Auto Control and Display …

Continue Reading250kgs per hour capacity waste incinerator

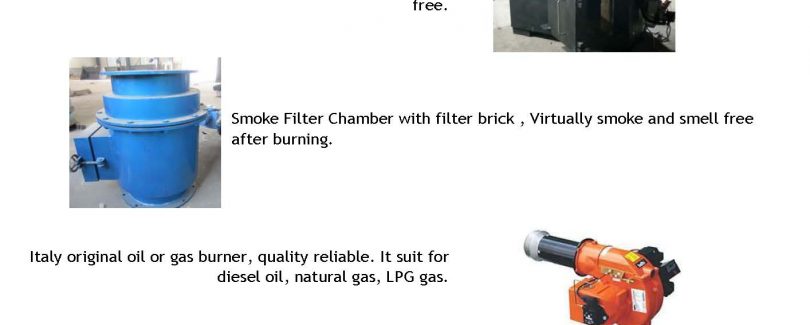

Incinerator Model TS250 PLC, Overview This model is small-scale waste incineration equipment for small waste output. Construction is dual/double combustion chamber with 02 units oil …

Continue ReadingTS Model PLC Control Waste Incinerators

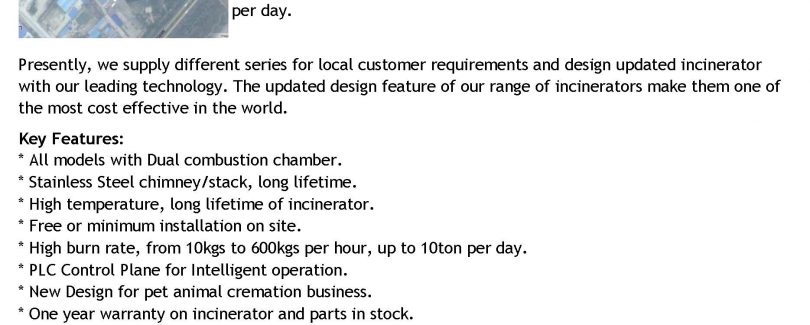

WWW.HICLOVER.COM|Waste Incinerators |Auto Roll Air Filters Nanjing Clover Medical Technology Co.,Ltd. Tel: +86-25-8461 0201 Mobile: +86-13813931455(whatsapp/wechat)Website: www.hiclover.com Email: sales@hiclover.comEmail: hicloversales@gmail.com Medical waste is posing a growing problem all over the world, jeopardizing the health of …

Continue ReadingHICLOVER INCINERATORS

Medical waste is posing a growing problem all over the world, jeopardizing the health of staff, patients, disposal workers and anyone else coming into contact …

Continue ReadingMobile Incinerator Containerized Incinerators Units

Mobile Incinerator Units to properly incinerate Solid Waste, Petroleum Oil, and Lubricants. Each Unit will be in accordance to the technical specifications/ operational capacity as defined below. Additionally, each Unit will provide Operation Manuals and Training Material.1)Process At Least 1 Metric Ton Of Waste Per Day2)Operable By 1 Person, With No Training Required3)Regular Maintenance Can Be Completed By 1 Person With Limited Training4)Regular Maintenance Should Not Exceed 1-Hour Per Day5)Complies With Euro / Or Us-Epa Emission Standards6)Ability To Incinerate Waste Petroleum, Oils, And Lubricants7)Tempratures During The Combution Process Must Exceed 1,500 °F For At Least 1-Hour8)Can Be Transported To And From Deployment Location In A 20-Foot Or Smaller Shipping Iso Container9)Capable Of 24 Hours Of Continuous Use10)Automatic Loading System 11)Automated Ash Removal System12)Gas Scrubbing System13)95% Reduction Of Solid Waste14)Operable With Diesel, Jp8, Or Fuel Oil15)Capable Of Burning 4 Units Of Waste Per Unit Of Fuel16)Able To Incinerate Combustible Waste To Include: Paper, Plastic, Cardboard, Food, Used Oils, Sludge, Oily Rags, And Wood Pallets.17)No Pre-Treatment Of Waste Required18)Vendor Repair Offered At Point Of Shipment19)Five (5) Year Component Warranty From Date Of Acceptance1)Operation Manual And Training Manual For Each Incinerator Provided As Part Of Bid Package2)Set Up And Installation Instruction Manuals Provided As Part Of Bid Package3)Blue Print/ Schematic Provided That Outlines The Physical Dimensions Of The 20-Foot Containerized Incinerators4)Delivery Plan To Explain The Movement Of 20-Foot Incinerators From Point Of Origin To Camp Arifjan, Kuwait5)Mobility Plan To Explain How To Move 20-Foot Incinerators From Base To Base Within Us Army Central Command Theatre6)Incinerators Composed With Heavy Duty Welded Construction7)Each Individual Unit Operated And Transported In A 20-Foot Iso Shipping Container8)Unit Can Be Fully Accessed, For Maintenance And Operation9)Primary / Secondary Temperature Controls10)Combustion Air Damper11)Vapor Tight Light Fixtures & 120v Outlet12)Outdoor Plug-In Receptable For Electrical Source13)Outdoor Fuel Train With Shut-Off14)Load Ramp15)Skid C Mounted Fuel Tank16)Electrical And Fuel Oil Connectors17)Control Panel And Air Louver18)Air Manifold Access And Utility Bulkhead19)Galvanized Shipping Covers20)Fuel, Water, And Oil Connector Lines21)Primary And Secondary Burners22)Fully Integrated Programmable Logic Controller (Plc) System23)Factory Tested, Wired Prior To Shipment24)Any Assembly And Disassembly Necessary For Operation Of The Unit Will Not Exceed 2-Hours, Must Be Able To Be Completed By 1-Person, And Does Not Require The Use Of Heavy Equipment (E.G. Forklift, Cranes, Etc.)25)Height Of The Entire System When In Operational Configuration (Measured From The Base Ofof The Container, To The Highest Point Of The Unit) Is Not To Exceed A Maximum Height Of 15-Feet.

Continue Reading